The Smartcode batch picking system allows you to pick multiple orders in one sweep using 'batched' picks. The batch picking system is configurable to your requirements but a typical system would batch orders into picks of 25 items grouped by their pick location.

To see more detail on how batches can be generated is available here.

To access your batch picks just tap the order list tab

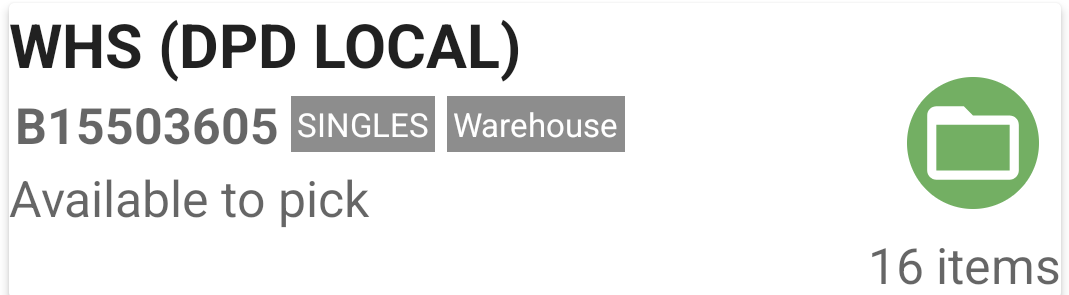

You will then see your list of batch picks, each batch has a traffic light system to prevent it being double picked. The statuses can be defined as

Green

A green batch is available for anyone to begin picking

Amber

An amber batch indicates that picking has commenced for the batch, but has not yet been completed and is not currently being actively picked (for example the picker has finished their shift)

An amber batch can be picked up for completion by any user.

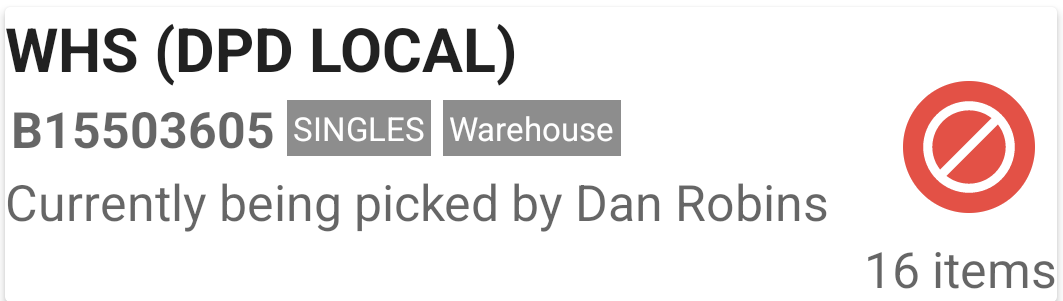

Red

A red batch is locked as it is currently being actively picked. No other users can access that batch.

To begin picking a batch tap on the batch name

You will then be prompted to scan a barcode of the tote to pack into

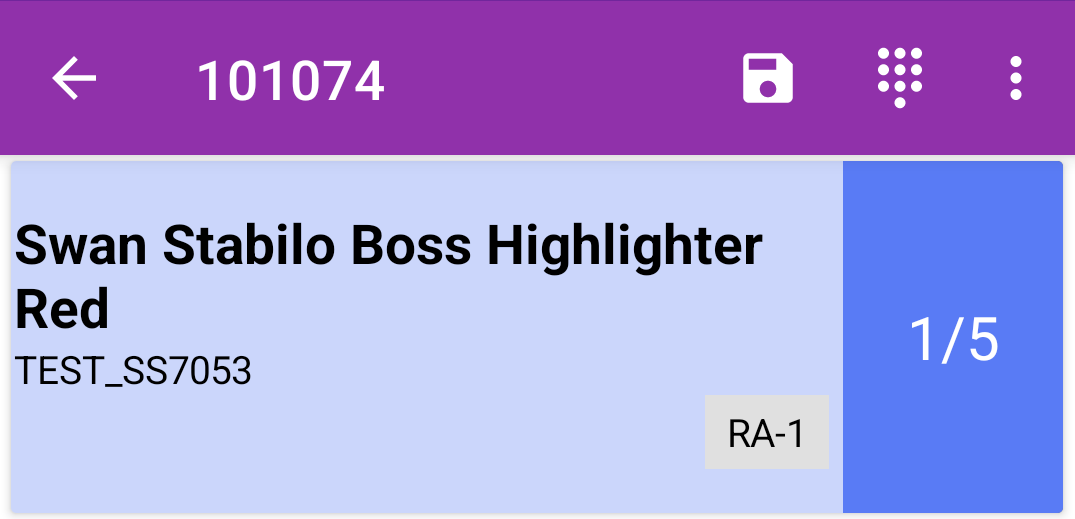

Once your tote barcode has been scanned you will see the items to pick. The pick and scan process is the same as picking a regular order.

Should the picker require an additional tote for the batch picks, totes can be added at any time using the 'Add Tote' menu option.

Once the pick is complete, the tote(s) are taken to the packing area to be split into individual orders.

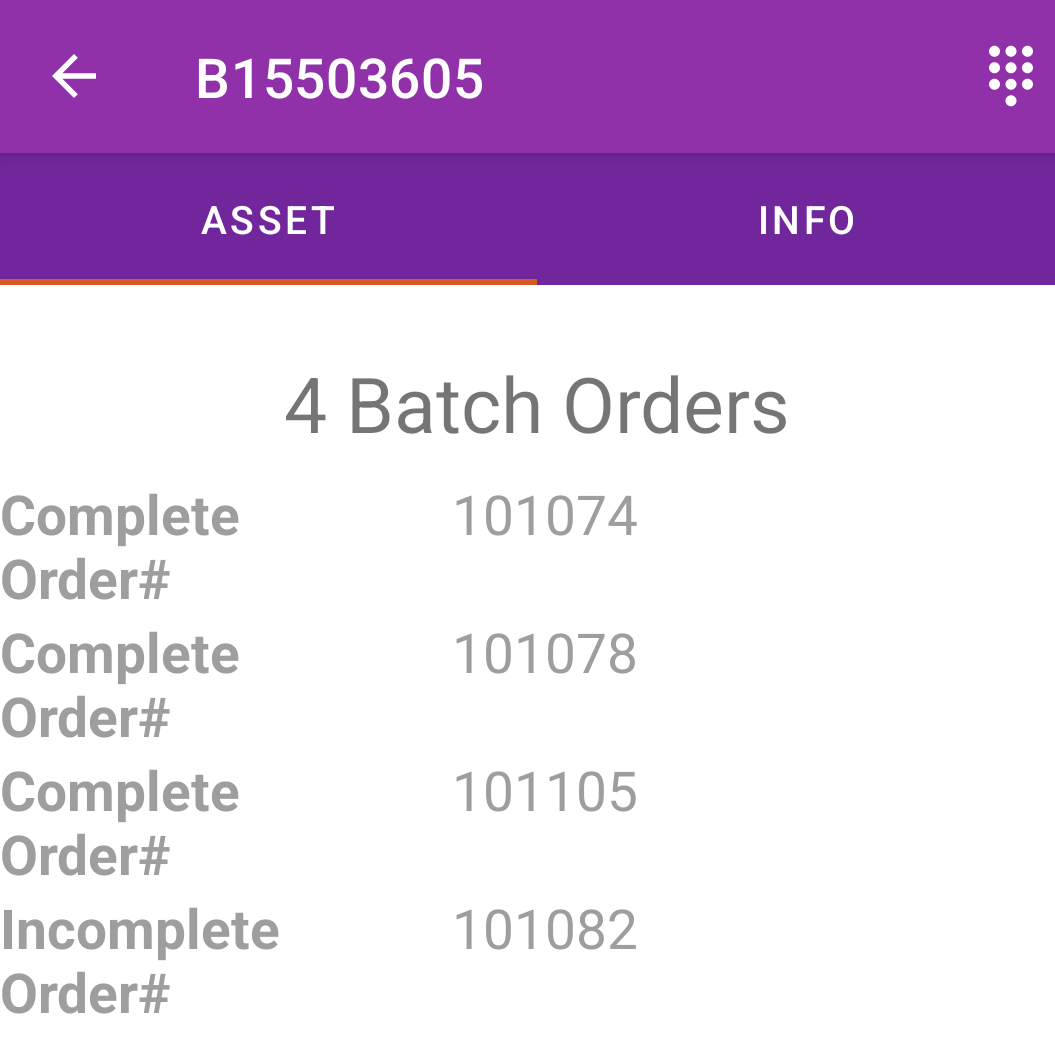

To begin the packing process the packer scans the tote the orders have been picked into. The Smartcode app will then display the completed orders within the batch.

From this screen, the user can then scan any item in the tote to display the individual order that the item belongs to

The item that was scanned will be marked as picked, the packer can then locate the other items that belong to this order from the tote and scan them to confirm they are correct.

Once the order pick is correct a packing slip will automatically print via a thermal label printer. If your system is connected for courier label printing the courier label will also be printed.

The packer can then proceed to take another item out of the tote to scan until all orders have been correctly allocated.

Batch Pick Logging

For audit purposes all batch picking activity is logged to your Smartcode order log,

- Batch pick allocation

- Tote scanning

- Packing slip print time

- Courier label print time